The Duravant family of operating companies serve the food processing, packaging and material handling segments.

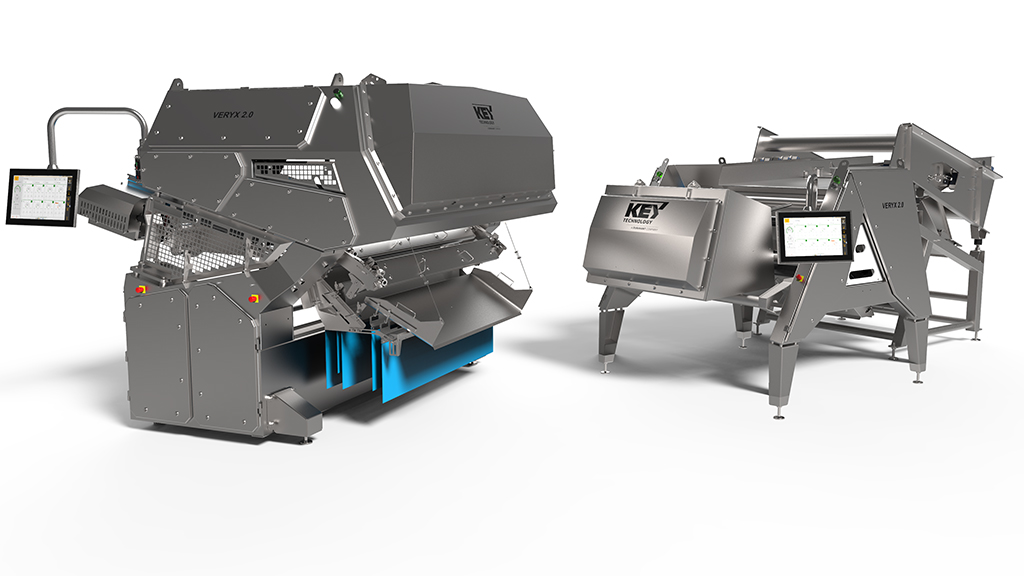

Industrial Cheese Processing Equipment & Vibratory Conveyors

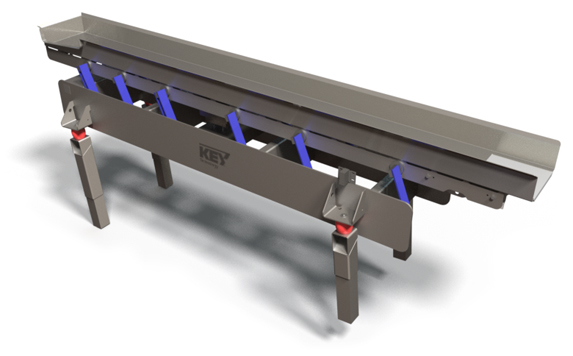

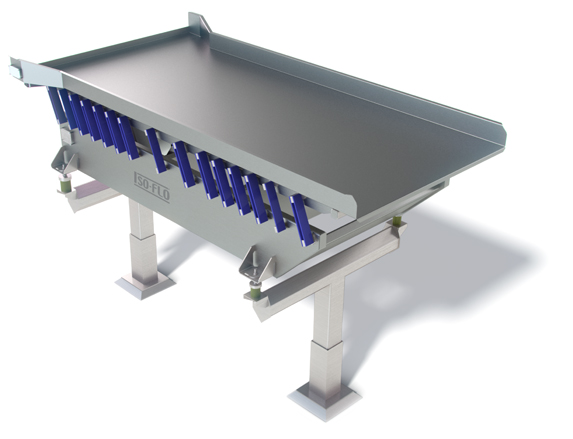

Key’s easy-to-sanitize inspection, conveying, feeding, metering, and other industrial cheese processing equipment for dairy products, including vibratory conveyors for cheese, consistently meet application requirements while cutting labor expenses and achieving the product safety standards that the USDA and your customers demand. With our industrial cheese processing equipment, processors ensure they always provide quality products that will meet consumer expectations.

Are you interested in learning more about our solutions?

Features That Drive Performance

Key’s dairy solutions are built to maximize productivity and ensure food safety:

- Sanitary, easy-to-clean designs – stainless steel construction and open-frame designs simplify washdowns and reduce contamination risks.

- Gentle product handling – vibratory conveyors move cheese without damaging texture or shape.

- Consistent metering and feeding – accurate product flow improves downstream efficiency.

- Regulatory compliance – all equipment meets USDA and FDA requirements for dairy processing.

- Durability and uptime – robust construction minimizes downtime and maintenance.

Benefits for Dairy Processors

By choosing Key Technology, processors achieve measurable improvements in efficiency and product quality:

- Lower labor costs through automation.

- Reduced product waste thanks to gentle conveying.

- Greater throughput with reliable, high-capacity equipment.

- Stronger consumer confidence with food safety built into every system.

Ready to Optimize Your Cheese Processing?

Key Technology’s industrial cheese processing equipment and vibratory conveyors help you deliver consistent, high-quality dairy products while meeting regulatory and customer demands.

Contact our team today to learn how our solutions can improve your operation.