The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Key Technology Introduces New Conveyor Systems for Poultry Processing and Packaging

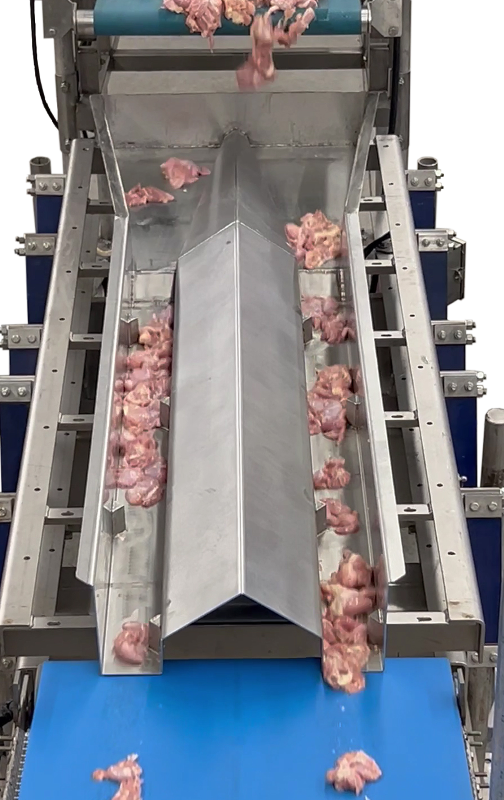

Key Technology (“Key”), a member of Duravant’s Food Sorting and Handling Solutions group, leverages the poultry processing expertise of Duravant brands Foodmate, Marelec, Marlen and Henneken to introduce their new vibratory conveying systems for poultry processing and packaging lines at IPPE booth #C-19136. These integrated systems meter, separate, singulate and/or align raw poultry products to create a monolayer for optimal presentation to downstream equipment including x-ray inspection systems, metal detectors, tray packing equipment and more. By automating this process, these vibratory conveying systems maximize production efficiency, increase throughput and minimize labor requirements while improving sanitation to protect product quality.

“Manually styling raw poultry for a downstream system is very labor intensive and a significant pain point for poultry processors who are struggling to find and retain workers at their plants. That’s why we designed this poultry conveying system, which can reduce labor requirements by more than 75 percent at this critical part of the line,” said Jack Lee, Duravant Group President – Food Sorting and Handling Solutions. “By replacing traditional belt conveyors with vibratory systems, we’re also helping processors improve food safety and prevent costly product recalls. Vibratory conveyors are substantially safer and more sanitary, reducing the chance of foreign material contamination like belt fragments and clips while eliminating common issues like fat build-up.”

Key designs, builds and tests each of their integrated conveying systems to identify the necessary speed, stroke, lane widths and step sizes to reliably present the processor’s products in the ideal configuration for the downstream equipment. With interchangeable screens that can accommodate different product types and sizes, these conveyor systems can be configured to handle different cuts of raw, non-frozen/pre-frozen poultry including deboned meat, bone-in wings, drumsticks, thighs and more.

Each integrated conveying system often begins with an optional shaker or belt conveyor for metering. Then, a separating shaker evenly spreads product, followed by a singulating shaker directs product into single-file lanes, when needed. The final shaker achieves optimal speeds for feeding downstream equipment.

Engineered for superior sanitation and minimal maintenance, every robust vibratory conveying system features an open frame design without cavities that harbor bacteria. It features 100-percent stainless-steel construction, including motors. With fewer moving parts than traditional belt systems, maintenance requirements are significantly reduced.

Key manufactures conveyors and other equipment in both the USA and Europe, supports its customers worldwide through an extensive sales network and global service team and offers integration services, from pre-engineering to line start-up. Key’s conveyor beds and structural components are backed by their industry-leading, 5-year warranty.

For more information, visit www.key.net.

About Key Technology, Inc.

Key Technology is a global leader in the design and manufacture of automation systems including optical sorters, conveyors and other processing equipment. Applying processing knowledge and application expertise, Key helps customers in the food processing and other industries improve quality, increase yield and reduce cost. Key manufactures its products in Walla Walla, Washington, USA; Redmond, Oregon, USA; and in Beusichem, the Netherlands. Key offers customer demonstration and testing services at four locations including Walla Walla and Beusichem as well as Hasselt, Belgium and Sacramento, California, USA; and maintains a sales and service office in Santiago de Queretaro, Mexico. Key is a Duravant Company. For more information, visit www.key.net.

About Duravant

Headquartered in Downers Grove, IL, Duravant is a global automation solutions and engineered equipment company with manufacturing, sales and service facilities throughout North America, South America, Europe and Asia. Through their portfolio of operating companies, Duravant delivers trusted end-to-end process solutions for customers and partners through engineering and integration expertise, project management and operational excellence. With worldwide sales distribution and service networks, they provide immediate and lifetime aftermarket support to all the markets they serve in the food processing, packaging and material handling sectors. Duravant’s market-leading brands are synonymous with innovation, durability and reliability. For more information, visit www.duravant.com.

Reader Inquiries:

Buffy Hagerman

Key Technology

150 Avery Street

Walla Walla, WA 99362 USA

Tel: +1 509 540 7415

bhagerman@key.net

www.key.net

Reader Inquiries:

Lene Boes

Key Technology

Bedrijfsstraat 6b

B-3500 Hasselt, Belgium

Tel: +32 (0) 11 26 70 38

lboes@key.net

www.key.net