The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Key Technology Introduces Sort-to-Grade® with Artificial Intelligence

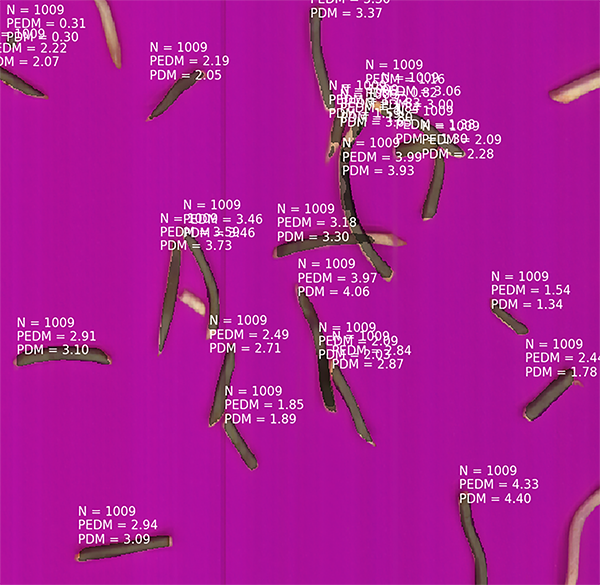

Key Technology, a member of the Duravant family of operating companies, introduces AI-driven Sort-to-Grade® (STG) at Pack Expo booth S-3547. Advanced AI algorithms allow STG for potato strips to digitally resolve clumps of overlapping product and better identify the individual strips, which maximizes its precision in measuring the length of each strip on the production line. Leveraging this powerful software on a Key digital sorter such as VERYX® enables potato processors to eliminate traditional mechanical length graders to reduce capital costs, maintenance and floorspace requirements while improving product quality and increasing yields.

“The next-level accuracy achieved with AI-enhanced STG facilitates new automation. Now, processors can eliminate mechanical length grading. They can also stop analyzing strip length off-line for QA purposes. And they have access to real-time length profile data to control upstream processes and better maintain final product specifications,” said Jack Lee, President of Key. “At Key, we’re continually developing next-generation automation that helps food processors reduce labor and increase profits. Artificial intelligence introduces many new opportunities to add value.”

STG recognizes and categorizes every surface defect and the length of every individual strip to make each accept/reject decision based on how it will impact the ‘in the bag’ grade, as defined by the processor. STG automatically ensures the most sophisticated length profile requirements are met while removing the least amount of product possible. For example, STG can be programmed to ensure that at least 20 percent of strips are longer than X mm, at least 30 percent of strips are longer than Y mm, no strips are shorter than Z mm, etc. Length profiles can be changed in seconds via the sorter’s intuitive touchscreen UI.

Dynamically managing length profiles with intelligent accept/reject decisions based on how each strip will affect the ‘in the bag’ grade, AI-enhanced STG increases yields by up to one percent more than the previous generation STG feature and generates a fast return-on-investment while helping the processor make grade.

By digitally monitoring the length of every strip on the line, processors can rely on an AI-driven STG-enabled sorter to analyze the length profile of potato strips immediately prior to packaging and forgo taking physical samples off the line for length analysis using a separate device.

Additionally, the length data collected by AI-enhanced STG can be used to improve line performance and/or generate reports that verify the length profile of each batch. With Key’s Discovery™ suite of software capabilities, the sorter can collect, analyze and share data to reveal patterns and trends that help control upstream and downstream processes.

The new AI-driven STG is an option available on every new Key digital sorter for potato strips including VERYX, and it is available as a field upgrade for most installed Key potato strip sorters.

About Key Technology, Inc.

Key Technology is a global leader in the design and manufacture of automation systems including digital sorters, conveyors and other processing equipment. Applying processing knowledge and application expertise, Key helps customers in the food processing and other industries improve quality, increase yield and reduce cost. Key manufactures its products in Walla Walla, Washington, USA; Redmond, Oregon, USA; and in Beusichem, the Netherlands. Key offers customer demonstration and testing services at five locations including Walla Walla and Beusichem as well as Hasselt, Belgium; Sacramento, California, USA; and Melbourne, Australia; and maintains a sales and service office in Santiago de Queretaro, Mexico. Key is a Duravant Company. For more information, visit www.key.net.

About Duravant

Headquartered in Downers Grove, IL, Duravant is a global engineered equipment company with manufacturing, sales and service facilities throughout North America, Europe and Asia. Through their portfolio of operating companies, Duravant delivers trusted end-to-end process solutions for customers and partners through engineering and integration expertise, project management and operational excellence. With worldwide sales distribution and service networks, they provide immediate and lifetime aftermarket support to all the markets they serve in the food processing, packaging and material handling sectors. Duravant’s market-leading brands are synonymous with innovation, durability and reliability. For more information, visit www.duravant.com.

Reader Inquiries:

Buffy Hagerman

Key Technology

150 Avery Street

Walla Walla, WA 99362 USA

Tel: +1 509 540 7415

bhagerman@key.net

www.key.net

Lene Boes

Key Technology

Bedrijfsstraat 6b

B-3500 Hasselt, Belgium

Tel: +32 (0) 11 24 91 91

lboes@key.net

www.key.net