The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Preventative Maintenance for Conveyors PLUS Special Parts Savings on StrongArm Spring Arms

January 2021

Conveyors are an integral part of any food processing operation and are often referred to as the “workhorses” of the plant. Robust, reliable and the ultimate multi-taskers, Key Technology’s conveyors can be used in numerous applications, such as collection, distribution, feeding, dewatering, grading, separating and more.

Preventative Maintenance for Conveyors

Vibratory conveyors from Key Technology are highly reliable, but do require proper use and regular maintenance to prevent problems. Three of the most common causes of shaker failure are cracked beds, cracked frames, and broken arm springs. These are all preventable and are caused by improper maintenance and/or running the shaker out of tune.

Always refer to your technical manual for detailed procedures on replacing arms and tuning your shaker, but here are a few tips to keep in mind when performing routine maintenance activities.

- Check that bed and frame are free from cracks and damage

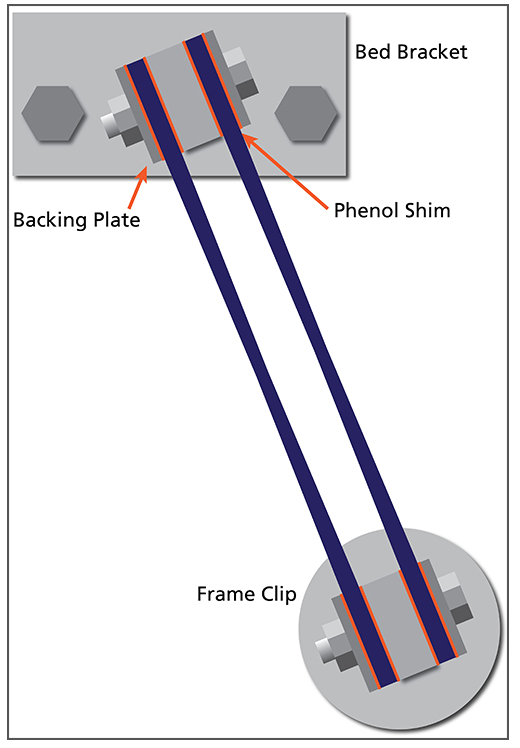

- Inspect spring arms and shims for condition, cracks and loose hardware

- Inspect drives for proper operation

- Ensure your shaker is operating at correct speed and stroke

Keeping a shaker ‘in tune’ – with perfect synchronization between the drives – is essential for reliable operation, whether the shaker is distributing, grading, aligning, scalping, feeding, or collecting. An out of tune shaker will disrupt the product flow and put excess stress on the shaker arms, bed and frame.

- The weight covers are dented – This causes the weights to rub on the cover and slow the drives, making them fall out of sync. If this is the case, the weight covers need to be repaired or replaced.

- The two drives are rotating in the same direction – This causes the shaker to become unstable. When replacing a drive, verify both drives are rotating in the correct directions.

- One of the drives is not spinning – This causes the shaker to become unstable but with less amplitude than if the drives are rotating in the same direction. Inspect the faulty drive to determine whether a repair or a replacement is needed.

- Product buildup on the shaker bed has added excess weight – This causes product flow issues and over stroking. To avoid this, ensure the shaker bed remains clear of product buildup.

One of the easiest and most important ways to keep your shaker in tip-top shape is to replace the arm springs at earliest sign of damage and on a regular basis. Check the spring arms, which will show damage in several stages:

- Stage 1 – damage appears around the holes

- Stage 2 – damage is evident by parallel lines running through the length of the fiber near the backing plate

- Stage 3 – appears as delamination of the layers, indicated by areas of lighter color

- Stage 4 – appears as cracking or fractures in the fiber near the backing plate

Stock Up & Save in February

During the month of February, save up to 10% on StrongArm® spring arms and phenolic shims for your Key Technology shaker:Don’t wait until you run out to restock these critical conveyor parts. Mark your calendar to place an order in February and take advantage of these limited-time* savings!