The Duravant family of operating companies serve the food processing, packaging and material handling segments.

The Right Service Contract for Your Business PLUS Maintenance for your Sorter Ejection System

August 2021

The Right Service Contract for Your Business.

Your Equipment Protection Plan

We understand your line operation, and are committed to your success. This commitment begins at installation and continues through the long-life of your equipment. Our tiered service contracts are designed to save you money, and to give you the right mix of tools and support to ensure your equipment performs consistently from the first hour of the processing season, to the last.

Three Reasons to Invest in an Annual Service Contract

- Emergency repairs can be expensive. Our service contracts can help protect against these unexpected costs by providing scheduled audits and remote monitoring. You can also choose a plan that offers emergency visits at no extra charge.

- Stock order programs allow discounted parts to be delivered ahead of time, making this the most cost-effective way to ensure all components are on site when you need them.

- Your Key Technology sorters, shakers, and processing systems are long-term investments that should be safe guarded. Our service contracts provide the greatest return on your investment by extending equipment life and optimizing its performance.

- Scheduled, in-depth audits and preventive maintenance increase the efficiency of your equipment for better recovery rates, consistent product quality, and maximum yield.

- Keeping your sorter up-to-date with software updates and patches ensures maximum detection performance and sorting accuracy.

- Our industry-leading remote monitoring service enables faster troubleshooting and issue resolution, ensuring maximum uptime and optimal performance and productivity.

- An effective preventive maintenance plan is proven to reduce the risk of unplanned downtime. Investing in a service contract means we can assist you in creating and executing a maintenance plan tailored for your specific machine.

- Planned inspections reduce the risk of unexpected repairs by allowing you to identify and address potential problems before they affect your processing line and lead to costly downtime.

- One of the most common causes of downtime is improper maintenance. Our certified technicians are experts on your equipment and can diagnose and resolve issues quickly and effectively. By investing in a service contract, you can feel confident that all repairs are done correctly.

Compare Protection Plans

- Growth Plan – a standard support plan with the added value of remote monitoring, pre-season audits, and onsite seasonal start up support.

- Optimization Plan – a comprehensive support plan that includes online training, pre- and post-season audits, and remote applications support.

- Enterprise Plan – our most extensive support plan adds free emergency visits and OEM electrical replacement components, onsite training, and software upgrades.

But that’s not all!

- Tailored Plan – need a fully customized service approach? No problem. Our service team experts can tailor a contract to fit your unique business requirements.

*Optional Services Based on Customers’ Needs

*Optional Services Based on Customers’ Needs

Effective Maintenance of Your Sorter Ejection System

An important enabler for a successful sort process is an effective preventive maintenance program for critical elements of your sorter The recommended maintenance schedule in your equipment manual contains information relative to a very important subsystem: the sorter air ejector. If the ejection system is running sub-optimally, the quality of your sort may degrade, and the sorter may fail to accurately separate certain items in the product stream.

The main elements of the ejection system are:

Air Ejection Valves

The air ejection valves are timed to remove product defects and foreign materials from your product stream, according to the sort recipe. These parts are highly used by the sorter, and after a time they may fail. The two modes a valve can fail are:

- Constantly enabled. In this failure mode the air valve constantly blows air. This may cause product under the area where the valve is located to be rejected on a continuous basis, until the valve is replaced. An easy way to troubleshoot a valve that is “stuck open” is to listen for the sounds of constantly blowing air from your sorter’s air ejector manifold.

- Constantly disabled. An air valve that will not enable and actuate, due to a failure of a valve component or other issue.

Air Ejector Driver Boards

The air ejector driver boards receive information from the sorter computer and tell individual valves to enable or disable at exact times. A faulty board can result in a group of valves that are disabled. Product defects may fail to be ejected and go into the sorter accept stream if this issue is not resolved.

Preventive maintenance will address these possible issues to prevent and minimize downtime; it is therefore important to follow your technical manual’s recommended maintenance intervals.

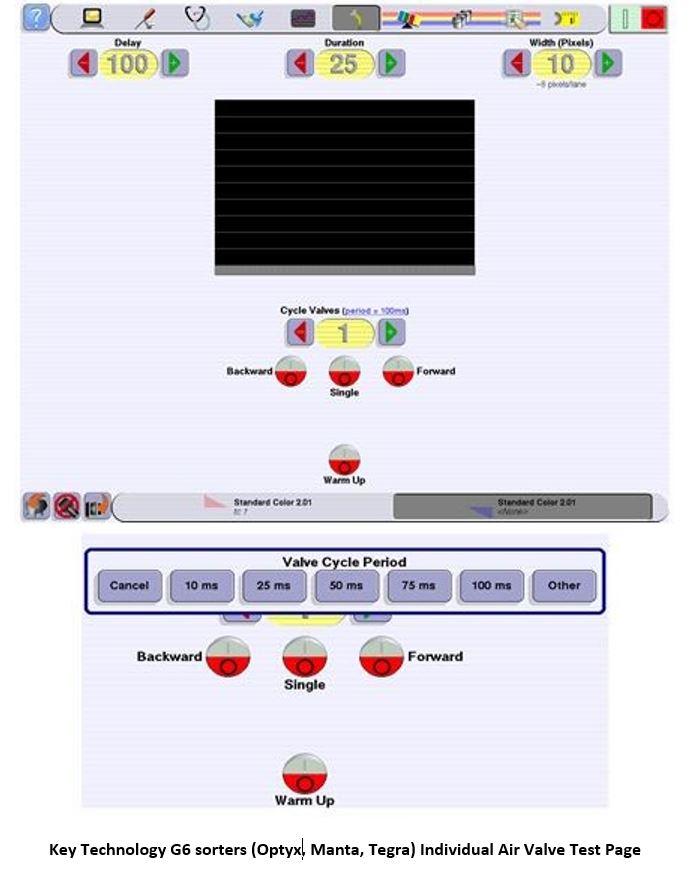

All Key Technology sorters have programmed test procedures that allow operators to cycle through each valve in the system, and see a visual indication of the ejection system performance. These tests help identify any failed valves, as well as faulty ejector driver boards. Key Technology sorters also have a test mode for identifying and investigating specific failed valves, and for testing replaced valves to ensure correct functioning.

With air ejectors and driver boards, safety is paramount. The air ejectors valves are under constant pressure and injuries could arise if the air is not turned off and bled down prior to performing maintenance on the manifold. Also ensure the air ejection system is shut off from any electrical input when working on or near the ejector driver boards. Please follow your technical manual and adhere to all safety warnings when working on the air ejection system.

A proper stock of ejection system components will allow you to quickly replace failed items, reduce downtime, and ensure your Key Technology sorter delivers its highest level of sort performance and accuracy.

Stock Sale!

Through the end of September, save on parts for your Key Technology sorter ejection system.

• Save 5% on orders up to $5,000 in value

• Save 8% on orders between $5,000 and $10,000 in value

• Save 10% on orders $10,000 or greater in value